No.66, Carretera Weiyi, Zona Industrial de Alta Tecnología Gexiang, Ciudad Ruian, Provincia de Zhejiang, China. +86-577-65566677 [email protected]

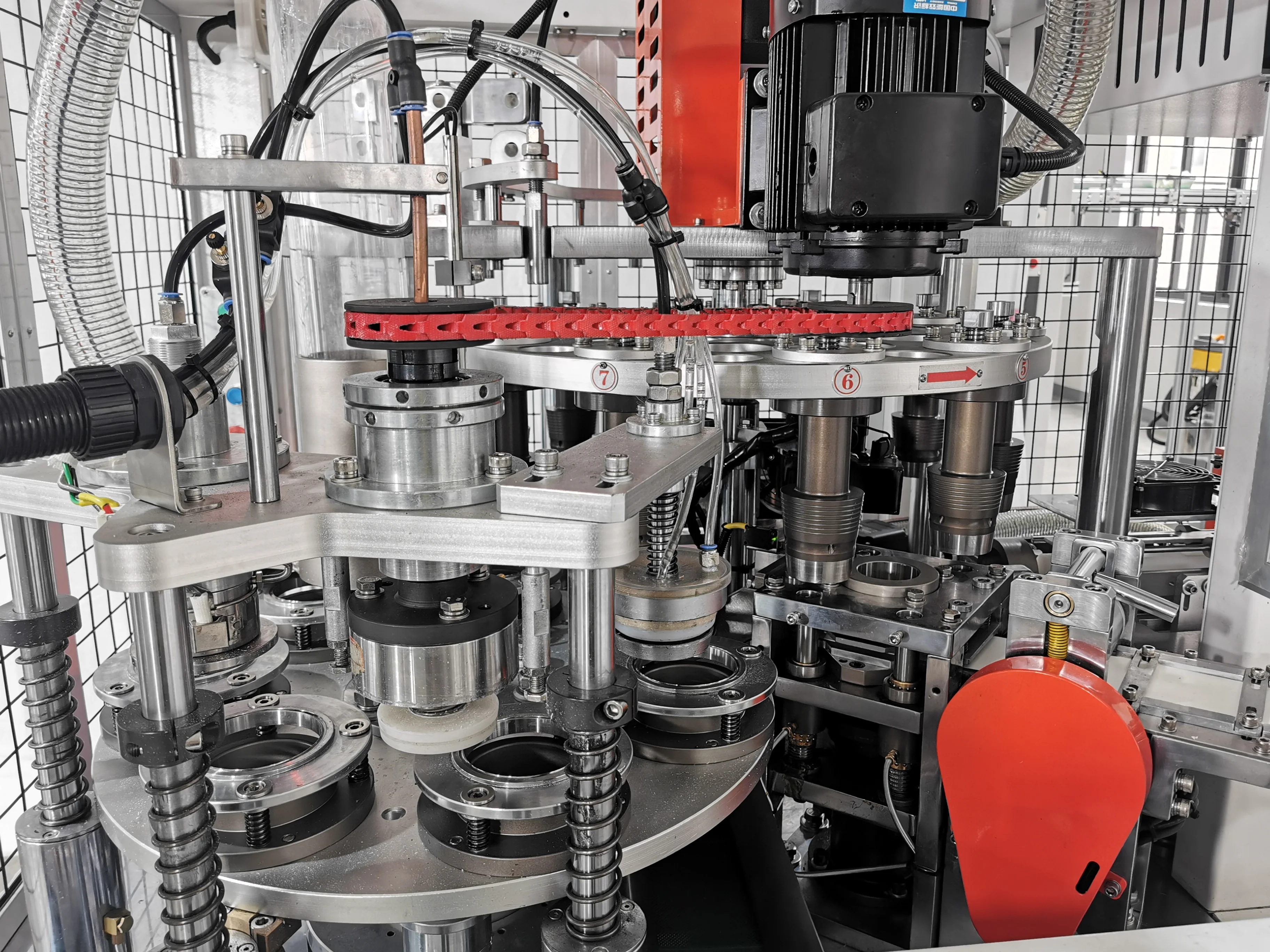

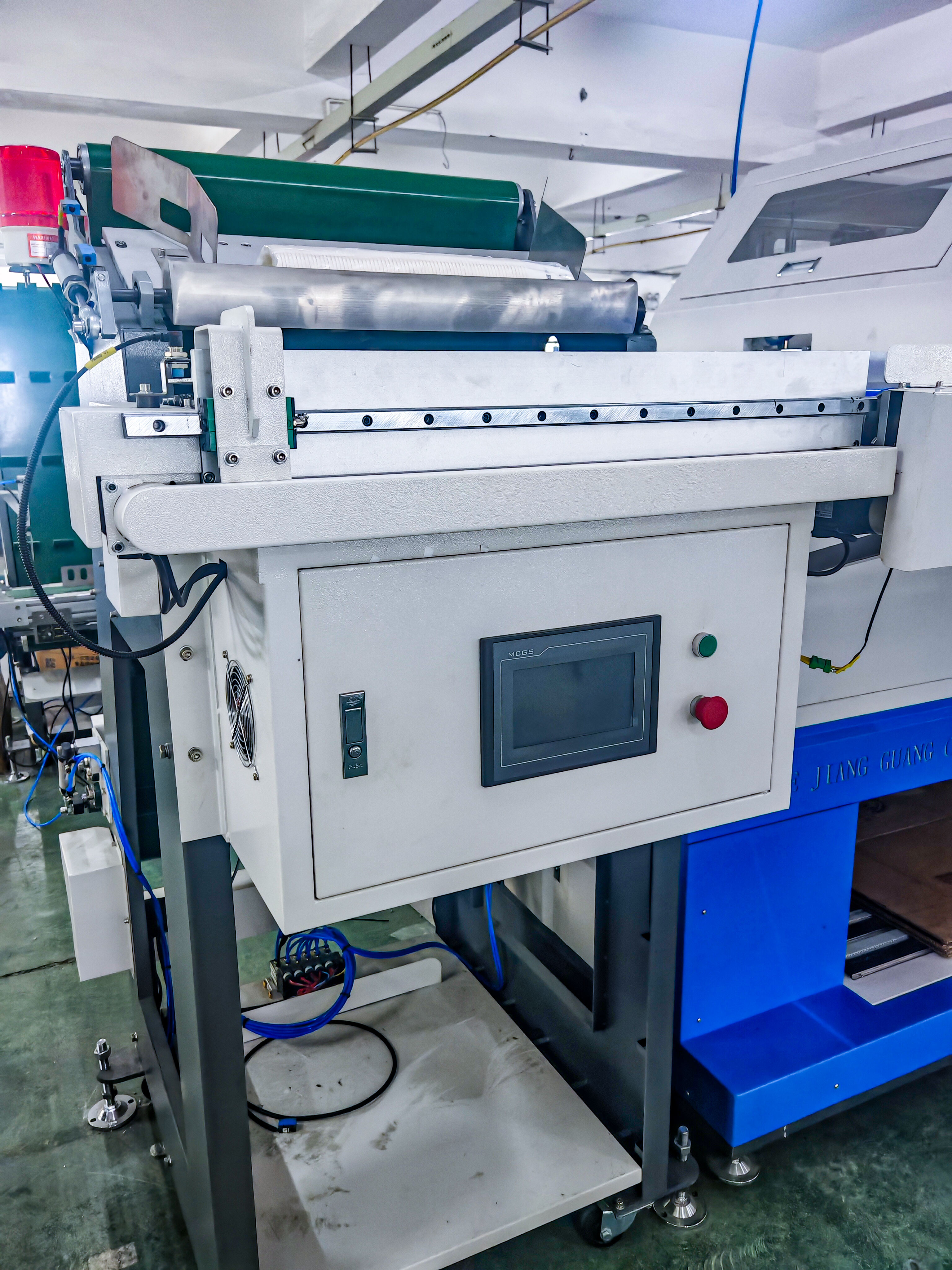

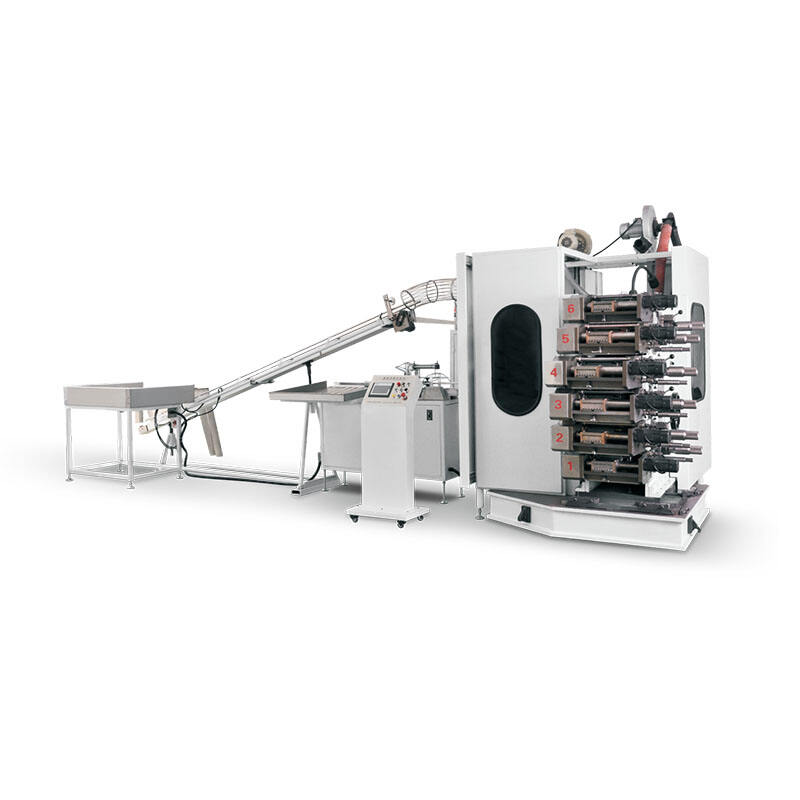

Phenomenal es nuestra nueva Máquina Automática de Termoformado de Tazas PP PET, una solución ideal para fabricantes que desean eficiencia, versatilidad y fiabilidad inigualables en envases desechables. Con el objetivo de fabricar productos y diseñada para producción continua, este modelo es verdaderamente el corazón de una operación moderna y rentable de envasado.