The Rise of Paper Cup Machines in Sustainable Packaging

Why Paper Cup Machines Are Key to Eco-Friendly Packaging Innovation

The latest paper cup manufacturing equipment makes it possible to produce compostable options on a large scale instead of relying on plastic packaging. According to recent industry data from the 2024 Packaging Materials Report, these new systems tackle around three quarters of the environmental problems caused by regular plastic cups because they work with materials that break down naturally. What's interesting is how different these machines are compared to older models. They actually cut down on energy consumption somewhere around 30-35%, yet still manage to churn out over 200 cups every single minute. This kind of efficiency represents a real breakthrough for sustainable manufacturing without sacrificing productivity.

Global Shift from Plastic to Paper-Based Disposable Products

Single-use plastic bans in 137 countries have accelerated adoption of paper alternatives. The Global Beverage Packaging Study shows paper cups now represent 43% of disposable drink containers, up from 28% in 2019. Coffee chains and food franchises drive this transition, with 92% of multinational QSR operators committing to full plastic phase-outs by 2026.

Growing Market Demand Driven by Environmental Awareness and Regulations

Consumer preference for sustainable options has propelled the paper cup machine market to a projected $8 billion valuation by 2026 (CAGR 4.5%). Regulatory pressures like the EU's Single-Use Plastics Directive (2019/904) and California's AB 1371 (2022) mandate paper-based solutions, creating urgent demand for production-scale machinery.

Role of B2B Adoption in Scaling Sustainable Packaging Solutions

Strategic partnerships between manufacturers and corporations account for 68% of paper cup machine installations. Systemic adoption by foodservice conglomerates reduces per-unit costs by 22% while diverting 17 million tons of plastic waste annually. This collaborative approach enables economies of scale critical for mainstream sustainable packaging transitions.

How Paper Cup Machines Contribute to Plastic Waste Reduction

Replacing Single-Use Plastics with Paper Cup Alternatives

The latest generation of paper cup manufacturing equipment is helping restaurants and cafes swap out hundreds of billions of those pesky single-use plastic cups each year for something that actually breaks down. Big names in the industry have cracked the code on making paper cups just as sturdy as their plastic counterparts but they disappear much quicker when tossed into landfills according to recent research from the Foodservice Packaging Institute (2023). These eco-friendly cups decompose about 94 percent faster than regular plastic. Since this shift started back in 2020, we've kept roughly 2.3 million metric tons of plastic trash out of our environment which amounts to taking nearly half a million cars off the road every single year if we think about it that way.

Biodegradability and Compostability of Paper Cups vs. Plastic and Styrofoam

Paper cups decompose in 2–6 months under commercial composting conditions, compared to plastic's 450-year decomposition cycle. A 2023 MIT study found plant-based linings reduce microplastic contamination by 78% compared to traditional polyethylene coatings. Though 22% of paper cups still require specialized recycling, newer models with algae-based barriers now meet industrial compostability standards (ISO 2024).

Environmental Impact of Traditional Plastic Packaging in Food Service

The food industry accounts for 36% of global plastic waste, with beverage containers representing 48% of shoreline pollution (UNEP 2024). Plastic-coated paper alternatives create 43% fewer greenhouse emissions during production than pure plastic cups. Despite this, only 9% of plastic food packaging gets recycled globally (Ponemon Institute 2023).

Quantifying Plastic Waste Reduction Through Widespread Paper Cup Adoption

Every 1% shift from plastic to paper cups eliminates 85,000 metric tons of plastic waste annually–enough to fill 6,500 garbage trucks. Major coffee chains report 12–18% plastic reduction per store after switching to paper cup machines, with bulk buyers achieving 42% waste reduction through optimized manufacturing processes (Circular Packaging Report 2024).

Innovations in Paper Cup Machine Technology for Sustainability

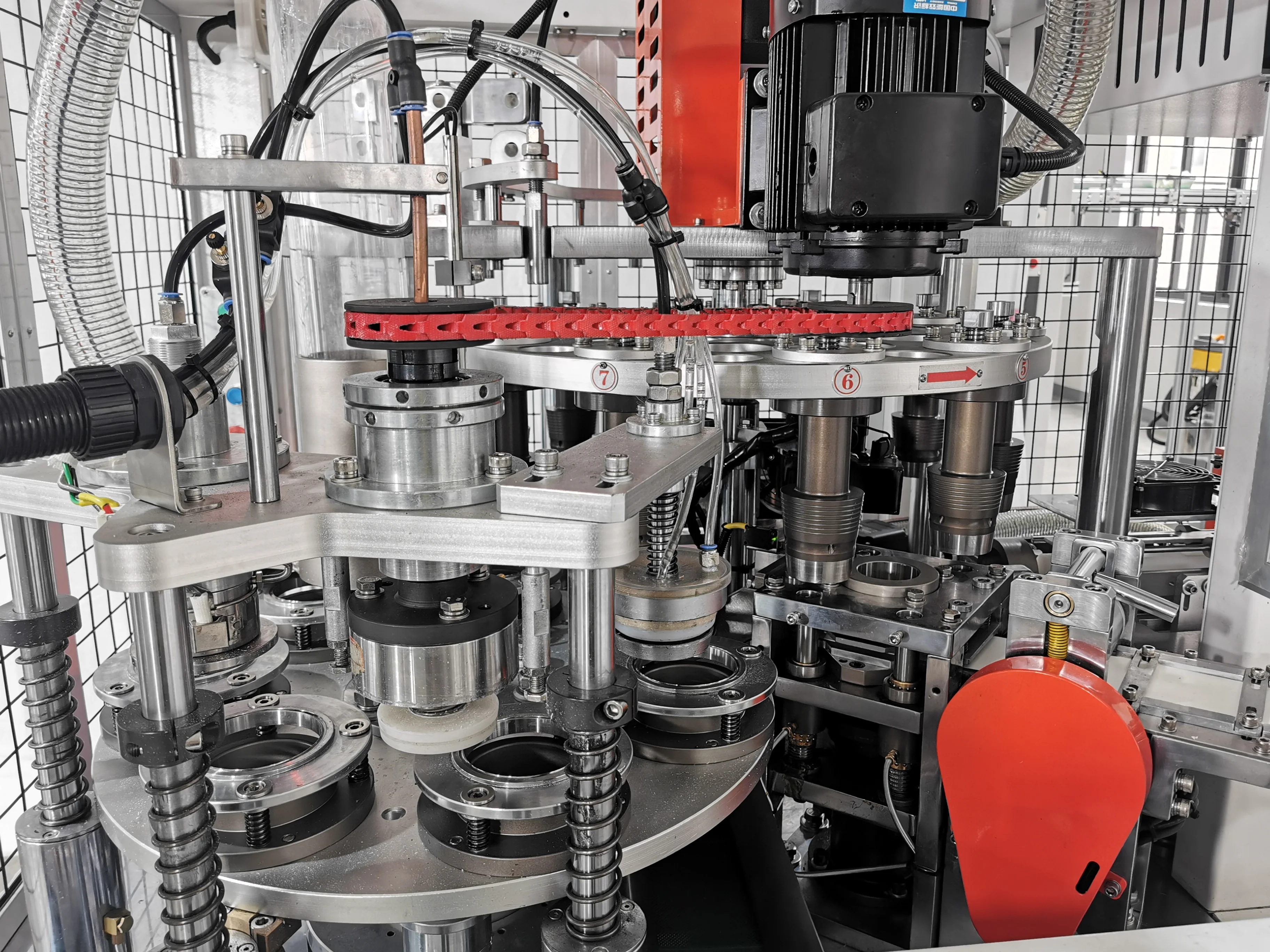

Advancements in Material Efficiency and Energy-Saving Production

The latest paper cup machines are getting around 30 to 40 percent better at using materials thanks to smart cutting patterns powered by artificial intelligence and those fancy servo controlled forming systems. This means factories waste about 18% less raw material overall. When it comes to saving energy, manufacturers have been implementing things like regenerative braking systems and heat recovery units which cut down on power usage. According to recent industry reports from last year, these improvements actually bring power consumption down by roughly 22% for every thousand cups made. And the results speak for themselves too. Factories equipped with this newer technology can churn out approximately 12,000 cups each hour while consuming only about 15% less energy compared to what was standard back in 2020.

Use of Biodegradable Linings and Recyclable Materials in Paper Cups

Leading manufacturers have introduced plant-based PLA (polylactic acid) linings that decompose 90% faster than polyethylene coatings, with 83% of new machines now compatible with compostable materials. Trials show paper cups made with starch-based barriers fully degrade in 12 weeks under industrial composting conditions, versus 450+ years for plastic alternatives.

Design Improvements: Minimizing Plastic Coating While Maintaining Functionality

Next-gen machines apply ultra-thin, water-based coatings (1.5–2 µm thickness) that use 70% less plastic than standard options while maintaining 98% leak resistance. Advanced extrusion systems precisely control adhesive distribution, achieving 20% stronger seams without additional material. This innovation alone prevents 8.2 million metric tons of plastic waste annually when deployed at scale.

Recycling Challenges and Solutions for Paper Cups

Barriers to recycling: Polyethylene lining and contamination issues

Paper cups are really hard to recycle because they're made up of multiple materials stuck together. The main problem comes from those plastic linings inside most cups that keep drinks from leaking through. These same features make them tough to break down at recycling centers. According to recent research published by ScienceDirect last year, around three out of four recycling plants simply don't have the equipment needed to separate the plastic from the paper part of these cups. And it gets worse when people leave old coffee or food residue inside. A study from Emerald Ecovations in 2024 found that about six tenths of all collected paper cups end up being thrown away instead of recycled because of this messiness. Global stats from Statista show we're only managing to actually recycle about one in eight paper cups worldwide. That's pretty shocking considering how many billions of these things get used every single day across offices, cafes, and events everywhere.

Emerging technologies for efficient paper cup recycling

The latest tech for separating materials can pull out those pesky polyethylene linings from paper cups at around 95% efficiency these days. What used to be trash ends up as usable paper pulp and plastic bits ready for reuse. Looking at newer designs, about one in four paper cups now features water based coatings that break down naturally. These eco friendly alternatives let companies create compostable cups while still meeting quality standards. Some cutting edge recycling centers equipped with smart sorting systems have seen their recovery rates jump by roughly 40% when it comes to handling these special coated papers. The numbers speak for themselves really.

Expanding global infrastructure for collection and processing

We've seen a pretty significant jump in specialized recycling spots at coffee shops and office buildings lately. The numbers are actually pretty impressive when we look year over year growth hitting around 30%, mostly because companies want to meet those EU guidelines on single use plastics. Manufacturers who make those paper cups have been teaming up with local recycling facilities too. They've set up something like 64 special processing centers throughout North America and parts of Europe since early 2022. Looking ahead, the whole sector is shooting for about half of all paper cups to get recycled by 2026. This goal depends heavily on better public awareness campaigns and creating consistent ways people can collect these cups from different locations.

The Future of Sustainable Disposable Packaging Beyond Paper Cups

Next-generation alternatives: Reusable, compostable, and plant-based solutions

The world of sustainable packaging has moved well past just paper cups these days. We're seeing all sorts of plant based stuff catch on, like those cool bamboo fiber containers and even polymers derived from seaweed. The compostable bioplastics made from farm waste actually break down much faster than regular plastic too. They can disappear in around 12 to 24 weeks if they end up in an industrial compost facility, while normal plastic takes hundreds of years to degrade. Some big name restaurants and coffee shops have started testing out reusable cup programs recently. These initiatives cut down on single use waste by about 80 percent when customers return their cups for a deposit refund. It's basically creating a system where products get used again and again instead of ending up in landfills after one trip.

Reducing waste from single-use beverage containers through systemic change

Waste reduction requires coordinated upgrades to recycling infrastructure and policy reforms. The EU's 2024 Packaging and Packaging Waste Regulation mandates 50% recycled content in disposable cups by 2030, accelerating circular design principles. Emerging technologies like integrated digital tracking systems enable real-time monitoring of cup return rates, helping businesses optimize reuse workflows.

How paper cup machines pave the way for broader sustainable packaging innovation

Paper cup machines today are showing us something pretty interesting about scaling sustainable practices in manufacturing. The thermoforming tech that was first made to create those water resistant cups we all know? Well it turns out this same technology works great for making compostable food containers too, especially when paired with those plant based liners that have become so popular lately. Manufacturers are starting to integrate solar power into their operations while also implementing AI systems that optimize materials usage during production runs. What makes this really exciting is that these setups offer practical models other companies can follow if they want to produce environmentally friendly packaging options without sacrificing volume or quality on an industrial level.

FAQ

What makes paper cup machines eco-friendly?

Modern paper cup machines use energy-efficient technologies and materials that decompose naturally, significantly reducing environmental impact compared to plastic cups.

How has the global shift from plastic to paper-based disposables impacted the market?

The shift has increased the demand for paper cups, leading to a projected $8 billion market valuation by 2026, driven by consumer preference for sustainable products and regulatory pressures.

What are the recycling challenges associated with paper cups?

Recycling paper cups is challenging due to their plastic linings and contamination from residues. However, new technologies are improving recycling processes by efficiently separating materials.

What innovations are being made in paper cup machine technology?

Advancements include better material efficiency, energy-saving production techniques, and the use of biodegradable and recyclable materials, reducing waste and environmental impact.

What future developments are expected in sustainable disposable packaging?

Future developments focus on reusable, compostable, and plant-based alternatives. These include innovations like bamboo fiber containers and bioplastics from farm waste that decompose much faster than regular plastic.

Table of Contents

- The Rise of Paper Cup Machines in Sustainable Packaging

- How Paper Cup Machines Contribute to Plastic Waste Reduction

- Innovations in Paper Cup Machine Technology for Sustainability

- Recycling Challenges and Solutions for Paper Cups

- The Future of Sustainable Disposable Packaging Beyond Paper Cups

-

FAQ

- What makes paper cup machines eco-friendly?

- How has the global shift from plastic to paper-based disposables impacted the market?

- What are the recycling challenges associated with paper cups?

- What innovations are being made in paper cup machine technology?

- What future developments are expected in sustainable disposable packaging?