The Shift to Sustainable Packaging: How Paper Cups Are Replacing Plastic

Rising Eco-Friendly Packaging Demand Due to Plastic Regulations

More than 120 countries around the world have put some sort of restrictions on single use plastics since last year according to UNEP data from 2023. This regulatory pressure has led to about a 27 percent jump each year in the need for machines that make paper cups. Places like Europe with their Single Use Plastics Directive and states such as California passing Senate Bill 54 are really forcing restaurants and cafes to switch over to biodegradable options. Looking ahead, experts think we'll see roughly 740 million dollars move from plastic products to paper based alternatives by mid decade. For businesses still stuck in old habits, this means now is definitely the time to start thinking green if they want to stay competitive in what's becoming an increasingly eco conscious marketplace.

Biodegradability and Consumer Preference for Paper Cup Solutions

Regular paper cups break down within about six months while plastic ones take an incredible 450 years to decompose, as noted by OECD data from 2022. This stark difference matches what we're seeing in consumer behavior these days. Around two thirds of people worldwide care deeply about eco friendly packaging options. And when it comes to younger generations, roughly eight out of ten millennials actually spend extra money on drinks packaged in compostable materials. The market trend is definitely pushing companies toward new solutions. We've seen rapid development lately in alternative plant based lining materials that can stand in for the usual polyethylene coatings found inside most disposable cups today. These innovations help make recycling easier without compromising on quality or functionality either.

Impact of Single-Use Plastic Bans on Paper Cup Machine Adoption

The push against plastic has really boosted paper cup machine sales in places where regulations apply, jumping around 33% since early 2022 according to recent data. Coffee shops across Europe and North America are swapping out roughly 19 billion plastic cups each year, something that's caught the attention of equipment makers who now see their ROI coming much faster these days. Some manufacturers claim their automated systems pay for themselves about 40% quicker than before. With stricter rules on the horizon, companies big and small are scrambling to scale up production capabilities just to keep up with what seems like endless demand from consumers wanting eco-friendly alternatives.

Government Policies and Incentives Accelerating Sustainable Packaging

Small and medium businesses are finding it easier to switch to sustainable packaging thanks to tax credits that cover around 15 to 30 percent of equipment expenses plus special grants for diverting waste from landfills. These financial incentives have led many companies to adopt eco-friendly packaging machines at impressive rates approaching ninety percent. The recent changes in the US Inflation Reduction Act set aside nearly 2.6 billion dollars over the next decade specifically for building out green packaging facilities across the country. A big focus area is developing recycling systems that work well with things like used paper cups which are notoriously hard to process. This kind of support makes sense for companies looking to invest in automated solutions while also incorporating more environmentally responsible materials into their operations.

Automation in Paper Cup Manufacturing: Boosting Efficiency and Output

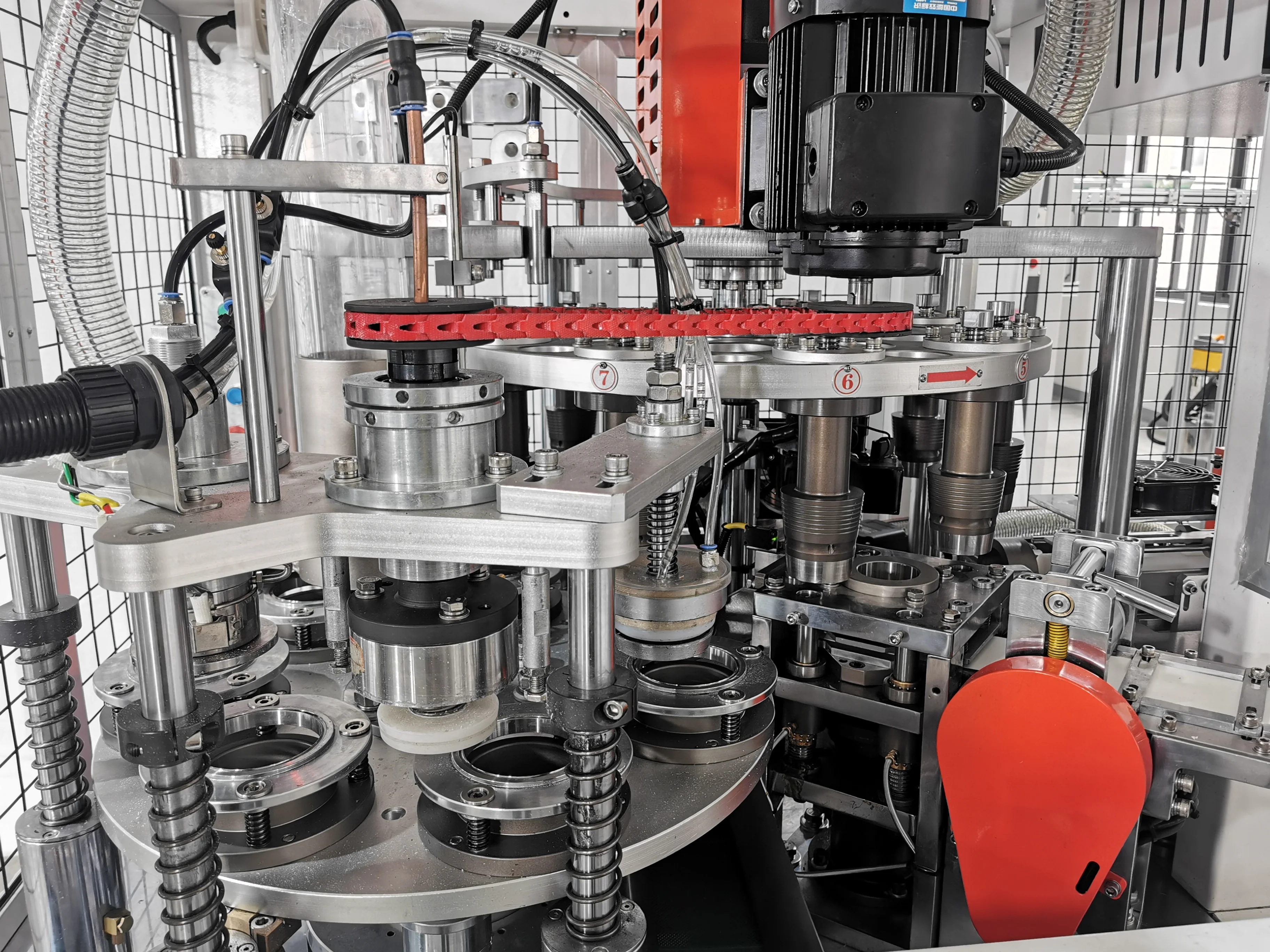

Innovations in Automatic Paper Cup Forming Machines

The latest generation of automatic paper cup forming machines now comes with built-in AI quality control systems that cut down on rejected products by around 37% when compared to what we saw in previous versions according to Growth Genius Insight from 2023. These machines have cameras watching every step of the process so they can spot flaws as soon as they happen without slowing things down much at all. Production lines typically run between 120 and 150 cups each minute which is pretty impressive considering how detailed the inspection has become. Big companies in the industry are also adopting smart platforms connected through the internet of things. With these tools, operators can tweak temperatures, pressures, and material flow remotely from anywhere. This means factories can keep running non-stop for days on end with minimal interruptions - most report less than 2% downtime overall.

Energy Efficiency and Smart Technology in Modern Machinery

Newer equipment cuts down on power usage around 18 percent thanks to regenerative braking tech and better heating components. The numbers back this up too smart sensors working with those predictive maintenance programs slash material waste somewhere around 26% as per some recent market research from 2023. What's really interesting though are the innovations happening right now. We're seeing machines that mix electricity with solar panels for power, cutting tools that adjust themselves within fractions of a millimeter accuracy, plus whole systems connected to the cloud that figure out when and where to allocate resources most efficiently during production runs. These improvements aren't just nice to have they're changing how manufacturers think about efficiency altogether.

Automatic vs. Semi-Automatic vs. Manual Machines: A Performance Comparison

| Feature | Automatic Machines | Semi-Automatic Machines | Manual Machines |

|---|---|---|---|

| Output Capacity | 120—150 cups/minute | 40—60 cups/minute | 10—20 cups/minute |

| Labor Requirements | 1 operator/3 machines | 1 operator/machine | 2 operators/machine |

| Error Rate | 0.8% | 2.5% | 6.1% |

| Energy Use per 1k Cups | 18 kWh | 24 kWh | 32 kWh |

Fully automatic machines dominate high-volume production environments, recovering upfront costs within 14 months due to round-the-clock efficiency. Semi-automatic models remain a practical choice for seasonal or mid-sized operations needing flexibility in output.

Market Growth Outlook for Paper Cup Machines (2025—2035)

Global Market Size and Forecast for Automatic Paper Cup Machines

According to Future Market Insights data from 2025, the worldwide market for automatic paper cup machines is expected to jump from around $1.7 billion this year to nearly $2.3 billion by 2035, growing at roughly 3% each year. Most of the action happens in high capacity machines that can churn out as many as 5,000 cups an hour, which made up almost half (46.7%) of all sales in 2025. Fully automated versions are becoming increasingly popular too, grabbing over half (52.4%) of the automation market share. The Asia-Pacific region remains the biggest driver here, thanks largely to fast paced city growth and booming restaurant chains throughout places like India and Southeast Asia where new eateries pop up constantly to meet rising consumer demands.

Key Growth Drivers: Hygiene Trends and On-the-Go Consumption

Since the pandemic hit, people just don't trust shared items anymore, so they want their food wrapped up in something they can throw away after one use. About two thirds of folks actually prefer those single use packages when grabbing a quick bite from restaurants or cafes. Delivery services and those convenience stores where you pick up stuff on your way home have made companies invest even more in making paper cups. Plastic restrictions started popping up all over the world back in 2022, and now there are bans in more than 120 countries. That opens up a huge market worth around 740 billion dollars for eco friendly replacements. Paper cups seem to be winning this race right now. Companies are getting busy building new equipment that works with compostable lining materials and printing with water based inks instead of traditional ones. They need these changes fast because regulations keep changing and customers expect greener options these days.

Applications Across Food, Beverage, and Retail Packaging Sectors

Widespread Use in Foodservice and On-the-Go Beverage Operations

Fast food places, coffee joints, and corner stores really need those paper cup machines these days if they want to run efficiently without trashing the planet. About seven out of ten quick serve spots already use automated systems for making cups because it cuts down on waste and saves money too. What makes these machines so popular? Well, they let businesses slap their logo right onto the cup and add that extra layer of insulation which keeps drinks warm longer. Think about your morning coffee or lunchtime soup - nobody wants a cold beverage after all! Looking at the bigger picture, the whole packaging automation business including our trusty paper cup makers is expected to hit nearly $10 billion by 2033 according to some market folks. This growth comes from how tightly connected everything has become between drink manufacturers and stores selling products.

Integration in Retail and Large-Scale Event Packaging Systems

More and more retailers and event planners are turning to paper cup machines when they need to handle big volume packaging without creating mountains of waste. Grocery stores install these at their bakery sections and deli counters where customers grab coffee or sandwiches on the go. Stadiums and concert venues roll out portable versions during busy weekends, serving literally thousands of fans each day. A recent market report from 2024 shows that about two thirds of major retail brands now look for machines that can make cups good for both drinks and snacks like popcorn or pretzels. The fact that these machines produce versatile products opens up all sorts of marketing possibilities with limited edition holiday designs or partnerships between brands. Plus, cities often require events with over 5,000 people to meet certain recycling targets, so having this equipment helps businesses stay within those rules without hassle.

FAQ

Why are paper cups gaining popularity over plastic cups?

Paper cups are gaining popularity due to stringent regulations on single-use plastics, which have led to an increase in demand for eco-friendly alternatives.

How do paper cups and plastic cups differ in terms of biodegradability?

Paper cups decompose within approximately six months, whereas plastic cups take about 450 years to break down.

What role do government incentives play in promoting sustainable packaging?

Governments offer tax credits and grants to businesses for adopting eco-friendly packaging, which has encouraged many companies to switch to sustainable options.

What are the main benefits of automated paper cup manufacturing?

Automated paper cup manufacturing systems enhance efficiency, reduce product rejections with AI quality control, and save on labor and energy costs.

What's the forecast for the global market for automatic paper cup machines?

The global market for automatic paper cup machines is expected to grow from $1.7 billion in 2025 to nearly $2.3 billion by 2035.

How are paper cup machines used in the retail and event sectors?

Retailers and event planners use paper cup machines to handle high-volume packaging while reducing waste. These machines cater to both drinks and snack packaging needs.

Table of Contents

- The Shift to Sustainable Packaging: How Paper Cups Are Replacing Plastic

- Automation in Paper Cup Manufacturing: Boosting Efficiency and Output

- Market Growth Outlook for Paper Cup Machines (2025—2035)

- Applications Across Food, Beverage, and Retail Packaging Sectors

-

FAQ

- Why are paper cups gaining popularity over plastic cups?

- How do paper cups and plastic cups differ in terms of biodegradability?

- What role do government incentives play in promoting sustainable packaging?

- What are the main benefits of automated paper cup manufacturing?

- What's the forecast for the global market for automatic paper cup machines?

- How are paper cup machines used in the retail and event sectors?