The Environmental Impact of Traditional Paper Cups

Understanding the ecological footprint of conventional paper cup making machine production

The traditional way we make paper cups is actually pretty wasteful. Every year, around 2 billion trees get cut down just for this purpose, and the whole process pumps out about 1.3 million tons worth of carbon dioxide equivalent emissions during production and shipping. Most paper cup manufacturing equipment depends on fresh wood pulp rather than recycled materials. A recent report from Sustainable Packaging in 2024 shows that roughly 70 percent of the energy used comes from fossil fuels and other non-renewable resources. What's worse, these standard manufacturing practices are driving up deforestation rates at an alarming pace. Some areas known for producing pulp have seen forest loss rise by nearly 12% each year because of this demand.

Challenges with recycling due to plastic linings in traditional cups

Most paper cups have this thin layer of polyethylene coating that makes them basically impossible to recycle through regular paper streams, which explains why so many end up in landfills instead. Even though those fancy high-speed machines can crank out around 400 cups every single minute, the reality is grim - only about 4 percent actually get recycled because of all that pesky plastic inside. Trying to separate those PE linings from the paper just costs municipalities extra money, roughly 28 percent more in processing expenses according to some recent research from Waste Management folks back in 2023. And things are getting worse for big manufacturers who now risk hitting their pockets with penalties upwards of $740 thousand each year as per EPA regulations from last year on extended producer responsibility laws. These financial hits might finally push companies toward better solutions for their disposable products.

Data on landfill accumulation and microplastic contamination from paper cup waste

| Metric | Annual Impact | Source |

|---|---|---|

| Landfilled paper cups | 740k metric tons | Ponemon Institute 2023 |

| Microplastic release | 5.2M particles per cup/year | Environmental Pollution 2023 |

| Methane emissions | 12kg CO2e per kg of waste | Global Composting Council 2024 |

Discarded paper cups take over 20 years to decompose, releasing methane equivalent to powering 50,000 homes annually. Microplastics from degrading PE linings are detected in 83% of urban groundwater samples near landfill sites.

Innovative Materials: Biodegradable Coatings and Renewable Fibers

Rise of PLA (Polylactic Acid) and Plant-Based Coatings as Sustainable Alternatives

The quest for greener paper cups really starts when we swap out those petroleum based coatings that have been around forever. Take PLA for instance, which comes from corn starch or sugarcane. According to some research published in the Journal of Cleaner Production back in 2020, about 38% of all new food-grade paper coatings worldwide are now made with this stuff. That's actually triple what it was just four years ago in 2018. What makes PLA so special compared to regular PE linings? Well, these coatings will break down completely in commercial composting plants within three months. Even better, they still keep drinks contained without leaking, even when hot beverages reach temperatures as high as 95 degrees Celsius or roughly 203 degrees Fahrenheit.

Advantages of Bio-Based Coatings in Food-Safe Paper Packaging

Bio-based coatings eliminate microplastic shedding—critical given that PE-lined cups release 25,000 microplastic particles per liter during degradation. Plant-derived alternatives like chitosan (from crustacean shells) and cellulose waxes offer comparable grease and water resistance while meeting FDA food-contact standards.

Bagasse Pulp and Agricultural Byproducts Replacing Virgin Wood Fiber

| Material | Annual Adoption Growth | Carbon Footprint Reduction vs. Virgin Fiber |

|---|---|---|

| Bagasse | 19% | 67% |

| Wheat Straw | 12% | 58% |

| Bamboo Pulp | 9% | 72% |

These agricultural waste streams now supply 31% of fiber for disposable cups, diverting 740,000 tons of biomass from annual incineration (2023 Sustainable Materials and Technology review).

PLA vs. PE Coatings: Performance, Cost, and Compostability Compared

While PLA carries a 15–20% cost premium over PE, its compostability aligns with tightening EU and North American single-use plastics regulations. PE coatings require specialized recycling accessible to only 9% of global consumers, whereas PLA breaks down in 84% of industrial composting sites.

Compostability Standards and Certification for Sustainable Cups

Industrial vs. home-compostable paper cup materials

For industrial composting to work properly, it needs those really hot conditions around 50 to 60 degrees Celsius that can keep going strong for about three months straight. That's actually required under the European standard called EN 13432. Now contrast that with home compost options which will slowly break down at regular room temps but might need anywhere from half a year to a full year to fully decompose. Only about 12 percent of cities across America even have access to these industrial facilities according to data from the Composting Consortium back in 2023. And here's where things get confusing for most people. A staggering 68% think that when something says it's compostable, it automatically means it'll disappear in their garden bin at home. But that just isn't true for most products out there today.

Key certifications: BPI, EN 13432, and FDA compliance in biodegradable packaging

Three certifications dominate sustainable packaging:

- BPI (Biodegradable Products Institute): Verifies industrial compostability in North America

- EN 13432: Europe’s benchmark for packaging biodegradation within 180 days

- FDA: Ensures food-contact safety for bio-based coatings

Manufacturers must balance these standards with regional infrastructure realities—only 14 countries globally have nationwide industrial composting networks (Green Packaging Report 2024).

Barriers to global adoption of compostable standards

The lack of proper composting facilities means certified compostable cups cost around 47% more than regular PE-lined ones according to Packaging Economics Review from last year. Things get even trickier when looking across borders. While European countries are ramping up their composting capabilities at about 12% per year, Asian nations are only managing growth rates around 3.8% annually as noted by Global Composting Initiative reports. And let's not forget about the equipment costs either. Machines needed to produce paper cups from bio-based materials typically demand capital investments that are 18 to 24% higher than standard setups. This financial barrier has been keeping many manufacturers from switching over completely, despite all the environmental benefits promised by compostable options.

Technological Advancements in Paper Cup Making Machines

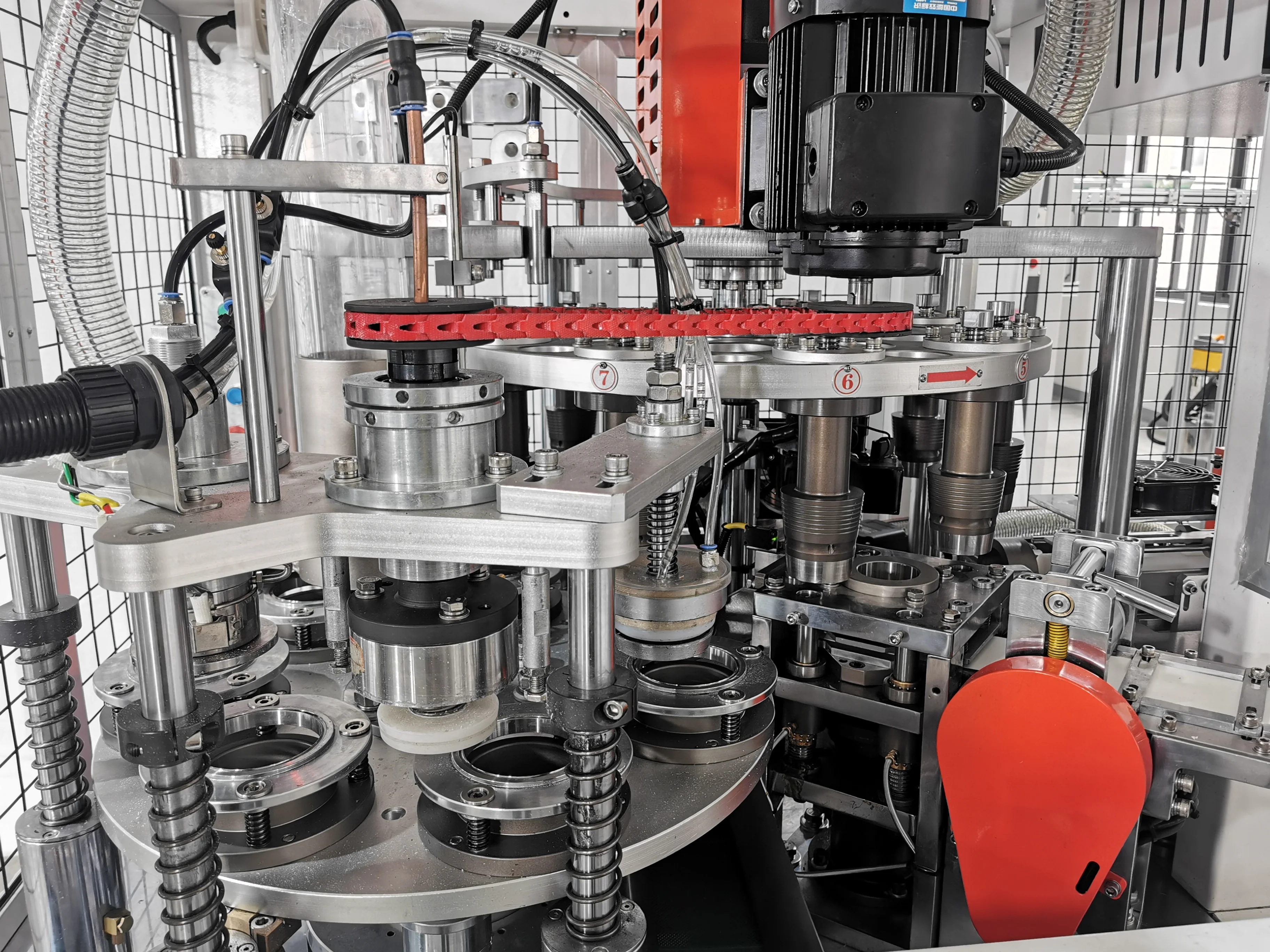

Machine Innovations Enabling Efficient Use of Biodegradable Materials

Today's paper cup manufacturing equipment handles plant-based coatings and PLA materials pretty well, which cuts down on production waste by around 22% when compared to older methods according to market reports from 2023. These machines use precision dies along with controlled temperature bonding techniques to maintain structural strength even with those biodegradable coatings. The cutting modules are driven by servos that really help maximize how much material gets used properly, especially important for making those complicated compostable sleeve designs. Trials have shown these systems can reach about 95% efficiency in material usage. We're seeing this trend across the packaging industry overall as manufacturers increasingly turn away from plastic made from fossil fuels toward more environmentally friendly automated solutions.

Smart Controls and Automation at Leading Manufacturers

Advanced PLC (Programmable Logic Controller) systems enable real-time adjustments for humidity-sensitive materials like bagasse pulp. Automated vision-inspection systems reduced defective output by 34% in IoT-enabled facilities (2024 study). Predictive maintenance alerts cut downtime by 18% annually, while AI-driven quality control enables 27% faster production speeds for double-walled biodegradable cups compared to manual oversight.

How Modern Paper Cup Making Machines Support Sustainable Packaging Transitions

Servo motors designed for energy efficiency can cut down on electricity usage by about 40% for every 1,000 items made. Meanwhile, heat recovery systems manage to capture around two-thirds of the wasted thermal energy during the sealing process according to data from the 2024 Sustainable Packaging Report. When companies integrate Industry 4.0 technologies, they get real-time tracking capabilities for carbon dioxide emissions too. Switching machines from polyethylene (PE) to polylactic acid (PLA) materials results in roughly 12 tons less CO2 emitted each year per unit. With these kinds of improvements happening across manufacturing lines, it's no wonder we're seeing nearly 58% more interest in compostable food service packaging annually. The market is clearly moving toward solutions that work both economically and environmentally.

Market Trends and the Shift Toward Eco-Friendly Packaging

Growing Consumer Demand for Sustainable Beverage Packaging

Industry surveys show 90% of consumers now prioritize recyclable or compostable cup options when purchasing beverages—a 35% increase since 2020. This shift, especially strong among Gen Z, drives brands to reconfigure paper cup making machine workflows for plant-based PLA coatings and industrial-compostable materials.

Impact of Single-Use Plastic Bans on Recyclable Paper Cup Innovation

Since 2022, 52 national governments have enacted plastic packaging restrictions, accelerating machinery upgrades by 18 months across the sector. Leading manufacturers are retrofitting equipment with temperature-controlled extrusion systems that apply bio-polymer liners at 40% lower energy than traditional PE laminations.

Corporate Adoption of Sustainable Packaging in Foodservice Industries

Seven of the top 10 global coffee chains have pledged to eliminate plastic-lined cups by 2026, driving $2.1B in projected investments for dual-purpose machines that handle both compostable fibers and recycled paperboard. These systems achieve £2% material waste through laser-guided forming technologies, aligning production efficiency with environmental goals.

FAQ

What is the primary environmental impact of traditional paper cups?

The production of traditional paper cups involves cutting down around 2 billion trees annually and contributes to approximately 1.3 million tons of carbon dioxide equivalent emissions. This is because most cups rely on virgin wood pulp and fossil fuels.

Why are traditional paper cups difficult to recycle?

The thin layer of polyethylene coating on traditional paper cups makes them nearly impossible to recycle through regular paper streams. This results in a majority ending up in landfills, contributing to environmental pollution.

What are some innovative materials being used as alternatives to traditional paper cups?

Innovative materials include biodegradable coatings like PLA (Polylactic Acid), which break down in commercial composting facilities. Other alternatives are plant-based coatings and fibers from agricultural byproducts like bagasse and bamboo pulp.

How do compostability standards affect the production of sustainable cups?

Compostability standards ensure that materials used in sustainable cups can break down in industrial composting facilities. However, industrial facilities are limited, making it challenging for compostable cups to be widely adopted.

What technological advancements are supporting the shift to sustainable paper cup production?

Advanced manufacturing machines now efficiently handle biodegradable materials, using technologies like servo motors, heat recovery systems, and AI-driven quality control to reduce waste and emissions in production processes.

Table of Contents

- The Environmental Impact of Traditional Paper Cups

- Innovative Materials: Biodegradable Coatings and Renewable Fibers

- Compostability Standards and Certification for Sustainable Cups

- Technological Advancements in Paper Cup Making Machines

- Market Trends and the Shift Toward Eco-Friendly Packaging

-

FAQ

- What is the primary environmental impact of traditional paper cups?

- Why are traditional paper cups difficult to recycle?

- What are some innovative materials being used as alternatives to traditional paper cups?

- How do compostability standards affect the production of sustainable cups?

- What technological advancements are supporting the shift to sustainable paper cup production?