Food Safety Compliance and Material Standards

FDA and EU Regulations for Food-Grade Certification of Paper Cups

Paper cup manufacturing equipment needs to follow pretty strict rules when it comes to materials that touch food products. The US Food and Drug Administration has specific guidelines about what kinds of inks, glues, and surface treatments can be used on cups. Every single part that touches the paper during production has to get official clearance before going into mass production. Across Europe things work differently but just as rigorously. There's this big regulation from 2003 that basically says manufacturers need to create barriers between the cup material and whatever goes inside so chemicals don't leach into food products. For companies selling their cups worldwide, getting certified under both American and European standards is becoming standard practice these days. It takes extra time and money but makes sense for businesses wanting access to multiple global markets without having to redesign their entire product line.

Use of Edible-Grade Paper Materials in Cup Production

For edible grade paper, purity is absolutely essential which means saying no to recycled fibers since they might bring along unwanted contaminants. Most quality manufacturers stick with virgin pulp from those FSC certified forests these days. They avoid chlorine bleaching because nobody wants to deal with the environmental mess or potential health issues that come with it. When it comes to lamination, there's a sweet spot somewhere below 5% of the overall cup weight. This keeps things sturdy enough to handle hot drinks around 95 degrees Celsius but still allows for proper recycling at the end of life cycle. Finding this balance remains a challenge for many producers trying to meet both performance standards and sustainability targets.

Ensuring Absence of Harmful Substances Like Fluorescent Agents

According to the 2022 BFR safety assessment guidelines, 12% of non-compliant paper cups fail due to trace levels of fluorescent whitening agents. To address this, advanced paper cup machines now feature inline spectroscopy systems capable of detecting optical brighteners at speeds exceeding 400 cups per minute, ensuring real-time quality control.

Compliance as a Market Access Requirement in North America and Europe

Traceability through digital means has become really important these days. About 40 percent of food packaging audits across Europe are now asking for detailed production records specifically from those paper cup manufacturing lines. Over in Canada things get even trickier because of the Consumer Packaging and Labelling Act which requires products to have labels in both official languages. This has led many companies to invest in laser coding systems capable of printing tiny compliance information at font sizes down to just 0.8 millimeters. And let's not forget the financial risks involved either. If businesses fail to meet regulations in certain markets, they could face fines running well over two hundred thousand dollars for each violation incident.

Safe and Sustainable Coating Technologies: PE vs. PLA

Polyethylene (PE) Coating for Water and Heat Resistance

Paper cup machines still mostly rely on polyethylene (PE) coatings because they keep drinks contained even when things get pretty hot, holding temperatures around 100 degrees Celsius without leaking. That's why we see these cups everywhere for our morning coffee or those steaming bowls of soup. But there's growing concern about environmental impact here too. Studies show that about two thirds of all microplastic pollution from beverage containers comes from these very same PE coated cups. As awareness spreads, manufacturers are starting to feel the heat to come up with greener options that don't compromise on functionality.

Biodegradable PLA Coatings: Safety and Performance in Paper Cup Machines

Polylactic acid (PLA), derived from corn starch, offers industrial compostability and aligns with the EU’s 2025 Single-Use Plastics Directive. While performance matches PE in cold applications, PLA has lower heat tolerance—safe only up to 60°C (140°F)—limiting its use for hot drinks unless paired with insulating layers.

Evaluating Chemical Migration Risks from Coatings to Beverages

| Factor | PE Risk Level | PLA Risk Level |

|---|---|---|

| Hot Liquid Leaching | Moderate | Low |

| Acidic Drink Reaction | High | Minimal |

| Long-Term Storage | High | Moderate |

Third-party testing shows PE-coated cups release 2.3 times more chemicals into acidic beverages than PLA-coated alternatives, though both remain within FDA migration limits (<0.01 mg/kg).

Balancing Environmental Goals with Food Safety in Coating Selection

The manufacturing sector is stuck between two tough choices here. On one side we have PE materials that keep food safe and perform well but really hurt sustainability efforts. On the flip side, PLA options align better with circular economy principles, though they frequently need changes to existing machinery to work properly. Some new hybrid approaches are starting to gain traction though. Companies experimenting with things like double layer PLA coatings or water based barriers report good results. These alternatives cut down on microplastic pollution quite a bit too, somewhere around 82 percent less than regular PE according to some recent industry research from PIRA in 2023.

Precision Engineering for Leak-Proof Cup Formation

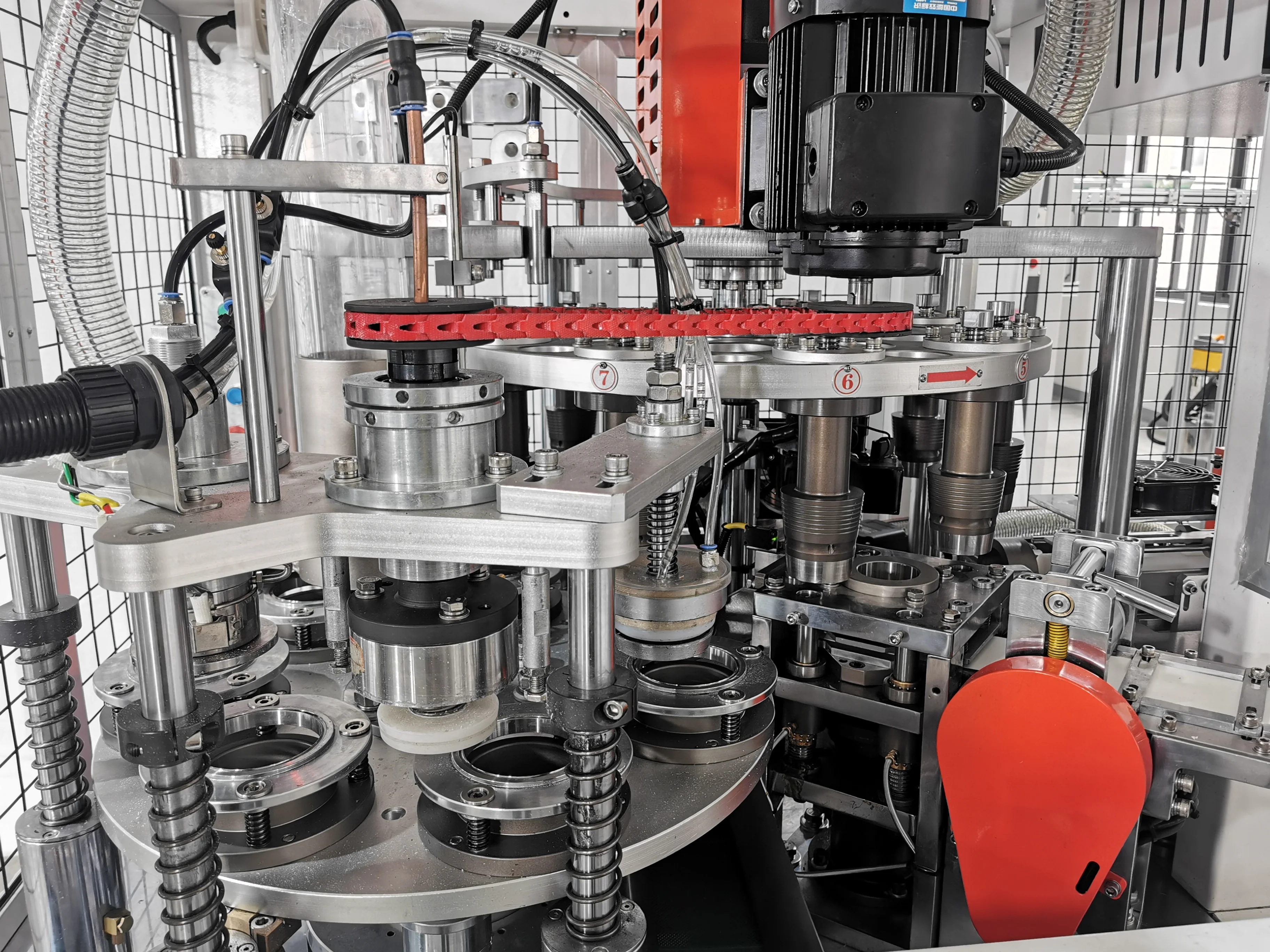

Engineering Precision in Rim Curling for Spill Resistance

Modern paper cup machines utilize micro-adjustable curling dies to form rims that balance structural rigidity with user comfort. Advanced systems employ laser-guided alignment to maintain tolerances within ±0.1 mm, eliminating the "zippered edge" defect caused by inconsistent folding. This precision prevents micro-leaks and enhances overall spill resistance.

Bottom Sealing Integrity Tests and Quality Assurance Protocols

Seal integrity is verified through a rigorous five-stage inspection process:

- Dry seal adhesion (â¥4.5 N/15mm peel strength)

- Hydrostatic pressure testing (withstands 30 psi for 60 seconds)

- Post-sterilization integrity checks (after 120°C steam exposure)

Inline pressure decay sensors detect air leakage above 5 cc/min—the threshold shown in recent material compatibility studies to prevent 98% of real-world failures—and automatically reject defective units.

Case Study: Reducing Leakage Incidents by 40% Through Process Optimization

One European company recently switched out their old equipment for smart paper cup machines that track temperatures in real time. These new machines brought down those annoying temperature swings during sealing from plus or minus 8 degrees Celsius all the way down to just 1.2 degrees. When paired with those fancy servo motor compression systems, something interesting happened. Customer gripes about leaks dropped dramatically over half a year period according to the latest Packaging Efficiency Report released in 2024. The numbers went from around 12.7% complaints to only 7.6%. And get this, the whole upgrade actually paid back the initial costs in just under a year and a half thanks to less wasted product and fewer warranty issues coming through the door.

Integrated Quality Control and Real-Time Monitoring Systems

Modern paper cup machines achieve near-zero defect rates through integrated quality assurance systems combining AI-powered inspection with real-time process monitoring. A 2023 Six Sigma Institute study found such systems reduce waste by 32% while maintaining 99.96% conformity to specifications.

In-Line Inspection Systems for Defect Detection in Paper Cup Machines

High-speed cameras equipped with AI analyze over 4,000 cups per minute for defects such as uneven rims or micro-leaks in coatings. Simultaneously, infrared sensors measure material thickness with ±0.03mm accuracy, flagging any deviations from FDA-approved parameters.

Automated Rejection Mechanisms for Non-Conforming Units

Pneumatic arms remove defective cups within 0.8 seconds of detection, preventing contamination of compliant batches. These systems maintain 98.7% accuracy in rejecting flawed units while operating at full line speed—up to 400 cups per minute.

Data-Driven Quality Control Using IoT-Enabled Paper Cup Machines

Real-time monitoring systems continuously track more than 18 process variables, including coating temperature variance (±2°C), pressurization during forming, and ambient humidity impacts on paper expansion. This data enables predictive maintenance and immediate corrective actions.

Human Oversight vs. Full Automation in Quality Control: A Practical Balance

Although automated systems handle 92% of inspections (2024 Packaging Technology Report), human technicians remain vital for:

- Hourly calibration checks

- Reviewing statistical process control dashboards

- Conducting destructive adhesion tests on coatings

Top facilities use hybrid quality management systems that integrate IoT analytics with expert oversight, achieving 40% faster anomaly resolution than fully automated setups.

Operational Safety Features for Machinery and Operators

Emergency Stop Functions and Guard Lockout Systems

For paper cup machines, having emergency stop systems certified under ISO 13849-1 is pretty much non-negotiable these days. The best ones can actually stop the whole operation within half a second once someone hits that button. Then there's the matter of those interlocking guards that keep the machine from starting up when it shouldn't. Maintenance workers report around an 83% drop in entanglement incidents since switching from old manual lockouts according to that Occupational Safety Report from last year. All this matters a lot in fast paced production settings where even a fraction of a second delay might mean the difference between a close call and something far worse happening on the factory floor.

Ergonomic Design and Safe Access Points for Maintenance

Leading machines incorporate light curtain sensors and retractable access platforms that maintain a minimum 18-inch safety buffer around moving parts. Ergonomic workstation designs reduce repetitive strain injuries by 40% through adjustable control panels and anti-fatigue flooring (Industrial Ergonomics Institute 2023), allowing safe servicing of blades and motors without full shutdowns.

Training Protocols for Safe Operation of High-Speed Paper Cup Machines

OSHA-compliant training programs emphasize:

- Pre-operation checks for hydraulic pressure and thermal controls

- Emergency drills for jam clearance and chemical spills

- Annual recertification on ANSI Z535 hazard communication standards

Facilities using VR-based training modules report 38% fewer incidents than those relying on traditional instruction methods (National Safety Council 2023).

FAQ

What are the key regulations for food-grade certification of paper cups?

The US FDA and EU regulations require guidelines regarding inks, glues, and surface treatments used in paper cups. Manufacturers must create barriers between the cup material and its contents to prevent chemical leaching.

Why is it important to use virgin pulp in edible-grade paper production?

Virgin pulp ensures purity and avoids contamination from recycled fibers, which might contain unwanted particles.

How do PE and PLA coatings compare in terms of environmental impact?

PE coatings are effective for heat resistance but contribute to microplastic pollution, whereas PLA is biodegradable and aligns better with sustainability goals but has lower heat tolerance.

What safety features are found in high-speed paper cup machines?

Safety features include emergency stop functions, ergonomic designs, and compliance with training protocols to prevent incidents.