Digital Inkjet Printing for Plastic Cup Printing Machine Revolutionizes Production Lines

Today's plastic cup printing equipment uses digital inkjet tech that gets colors right about 98% of the time and cuts down on wasted materials during setup by around three quarters when compared to old school screen printing methods. What this means for manufacturers is they can now afford to run smaller print jobs without breaking the bank. Some companies are even producing runs as low as 500 cups at a reasonable price point. According to recent market research from GlobeNewswire in 2025, the industry has seen roughly 14% yearly growth in adopting these digital printing solutions throughout various disposable packaging markets. Part of why this trend is catching on so fast relates to how well it works with eco friendlier water based inks plus the ability to create those fancy gradient effects that were previously impossible with conventional techniques.

High-Speed Digital Cylinder Printers Enable Mass Customization

Top manufacturers are rolling out rotary digital presses that can crank out around 2800 cups per hour while maintaining registration accuracy below 0.01mm. What makes these machines stand out is their ability to handle variable data printing everything from serial numbers to seasonal graphics and region-specific branding all without bumping down production speeds. One big name in beverages slashed their stock keeping unit (SKU) count by nearly two thirds after adopting this tech. They managed to print twelve different custom designs at once right there on the same production line, which completely transformed how they manage inventory and meet local market demands.

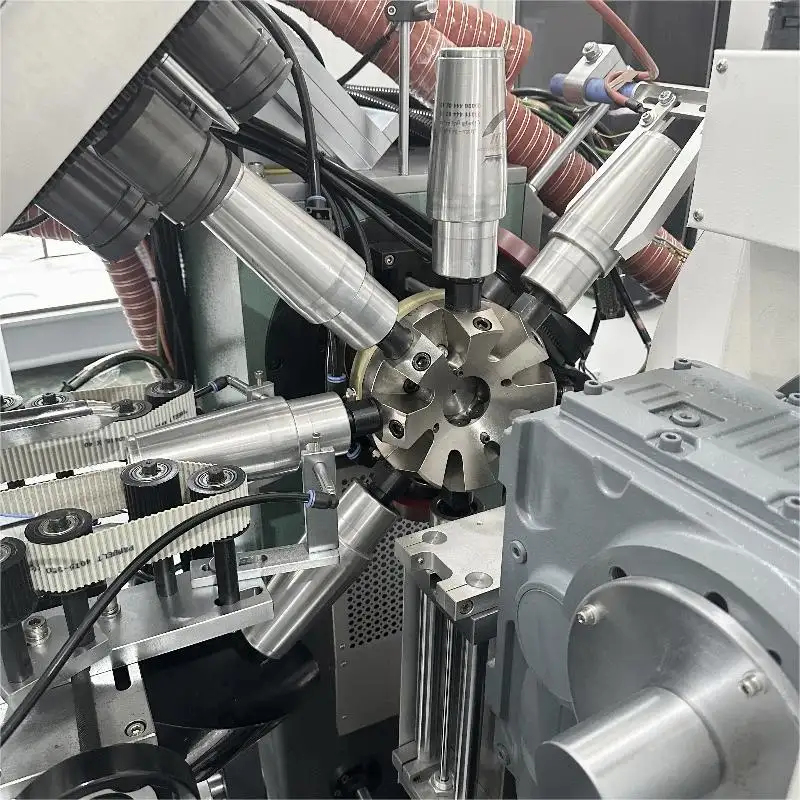

Integration of Automation in Cup Printing

Robotic arm integration has reduced manual cup handling by 90% in advanced facilities. Multi-station machines now perform inline processes:

- UV curing after printing (1.2 sec/cup at 395nm wavelength)

- Automated thickness verification (±0.05mm tolerance)

- Vision inspection at 120fps with 5μm resolution

This automation enables lights-out production, with some plants operating 22hr/day at 85% overall equipment effectiveness (OEE).

Precision and Speed Benchmarks

Current-generation plastic cup printing machines achieve:

| Metric | Performance | Industry Standard (2020) |

|---|---|---|

| Throughput | 4,500 cups/hr | 2,200 cups/hr |

| Positioning accuracy | ±0.1mm | ±0.3mm |

| Ink consumption | 8mL/100 cups | 15mL/100 cups |

These advancements allow brands to print 360° designs on 8oz PET cups in 2.3-second cycles while maintaining food-grade safety compliance.

Comparison of Key Plastic Cup Printing Machine Methods and Print Quality Outcomes

Screen Printing, Pad Printing, Dye Sublimation, DTF, and Digital Inkjet: A Performance Comparison

Today's plastic cup printing equipment offers several main methods, each bringing something different to the table when it comes to operation. Screen printing works best for large orders, producing sharp images at around 85 to 100 lines per inch resolution. The colors come out bright and solid, making this method great for straightforward logo work on cups. Pad printing handles those tricky curved surfaces pretty well, especially on cups that taper towards the top or bottom. However, getting multiple colors aligned properly can be challenging with this technique. Then there's dye sublimation which creates those beautiful wraparound designs without visible seams. It does require some special preparation though since the cups need to have that specific polyester coating first before the heat transfer process works properly.

Digital inkjet printing provides unmatched flexibility for small batches, achieving 1,200 dpi photo-realistic prints without screen setups—a 43% faster setup time than analog methods (ReliancePak 2023). Direct-to-Film (DTF) bridges the gap between digital and traditional methods, applying adhesive film transfers for detailed graphics on textured plastics.

| Method | Best For | Durability* | Color Gamut |

|---|---|---|---|

| Screen Printing | Bulk orders, spot colors | 5/5 | 85% CMYK |

| Digital Inkjet | Short runs, gradients | 4/5 | 98% CMYK |

| DTF | Textured surfaces | 4.5/5 | 95% CMYK |

*Durability tested per ASTM F2357 abrasion standards

Direct Printing Technology on Cups vs. Traditional Labeling Techniques

Direct printing cuts down on both material waste and those sticky label adhesives that eat into budgets. Companies report savings between 18% to maybe even 27% per unit when running mid-sized batches. Traditional label application needs extra equipment sitting around the production line, but newer plastic cup printers actually work right alongside the main manufacturing process. The precision here matters a lot too. These machines hit about 0.3mm accuracy when matching up with embossed details or molded features on cups something most branded products rely on heavily these days for their distinctive look and feel.

Evaluating Print Resolution, Durability, and Color Accuracy Across Methods

Resolution capabilities now reach 1,440 dpi in advanced digital cup printers, enabling micro-text and gradation effects previously exclusive to offset packaging. Accelerated aging tests show:

- UV-cured inkjet prints retain 90% color fidelity after 200 dishwasher cycles

- Screen-printed solvent-based inks achieve 500+ scrub cycles but lack gradient precision

- Plasma pre-treated cups boost ink adhesion by 40%, crucial for carbonated beverage packaging

Hybrid systems combining digital inkjet with robotic pad printing stations now address the durability-resolution tradeoff, achieving 4/5 scratch resistance at 1,200 dpi—a 22% improvement over standalone methods.

Enabling High-Quality Prints: Pre-Treatment and 360-Degree Helical Printing Innovations

Pre-treatment methods (corona and plasma) enhance ink adhesion on plastic surfaces

Using advanced treatments such as corona discharge or plasma etching can actually make a big difference when it comes to printing on plastic cups. These methods basically roughen up the surface at a microscopic level, which helps printed ink stick much better than on regular untreated plastics. According to recent research from Material Science Journal back in 2023, we're talking about around 60% improvement in how well the ink adheres. What these treatments do is change the surface energy properties down at the molecular scale. This makes all the difference for modern printing technologies like water based inks and those UV curable ones too. Both types work far better on treated polyethylene and polypropylene materials because they form stronger bonds with the modified surface rather than just sitting there waiting to flake off.

Case Study: Leading manufacturer’s plasma treatment increases print durability by 40%

A 2023 field study demonstrated that manufacturers implementing plasma pre-treatment systems achieved 40% greater print durability across 1,000+ dishwasher cycles, with ink adhesion maintaining ISO Class 4 standards throughout product lifespans. The technology reduced ink waste by 22% compared to traditional corona methods through precise energy modulation.

360-degree helical printing enables seamless, full-wrap cup designs

Today's plastic cup printing equipment uses helical imaging technology to create full circle designs around cups at blistering speeds over 4,500 per hour. According to manufacturers in the field, these all-in-one digital systems cut down on setup time by about three quarters when compared with older multi-pass models, plus they hit pretty impressive registration accuracy within 0.1mm either way. What makes helical printing stand out is how it places ink droplets in an overlapping pattern that gets rid of those annoying bands people sometimes see with single pass methods. This results in sharp images at 900 dots per inch resolution, which means gradient colors look much smoother and more lifelike on finished products.

Trend: Consumer demand for customized cup designs drives adoption of full-wrap digital systems

According to the latest Packaging Trends data from 2024, around two thirds of shoppers actually want their own custom drinkware these days. That's why many companies are moving away from keeping huge warehouses full of generic products and instead investing in smaller digital printers that can crank out runs starting at just 50 items without charging extra fees for setup. The market has really taken off with full wrap printing too - about 4 out of every 10 new plastic cup machines installed last year came equipped for this feature. Why? Because people love those special edition cups for concerts, festivals, and other events where having something unique makes all the difference.

Sustainability, Efficiency, and the Shift Toward In-House Plastic Cup Printing

Efficiency Gains Through Integrated Digital Workflows and Reduced Changeover Times

Modern plastic cup printing machines achieve significant efficiency improvements through automated workflows. By integrating smart sensors and real-time monitoring, manufacturers reduce changeover times by 35% compared to manual systems. This optimization allows single production lines to handle multiple design variations without downtime—critical for meeting demand for limited-edition packaging.

Reducing Label Waste and Packaging Materials via Direct Digital Printing

Direct digital printing eliminates traditional label application, cutting material waste by 40–60% according to 2023 circular packaging studies. Unlike adhesive-backed labels requiring additional backing layers, digital inkjet systems apply designs directly onto cups. This method reduces reliance on non-recyclable liners while maintaining print durability across 50+ wash cycles.

In-House Plastic Cup Printing Advantages: Faster Turnaround, Design Control, and Cost Savings

Brands bringing production in-house report 50% faster time-to-market for new designs while reducing per-unit costs by 18–22%. On-demand printing capabilities enable real-time design adjustments—particularly valuable for seasonal campaigns and regional customization. A leading manufacturer’s compact system demonstrates ROI within 14 months through reduced outsourcing fees and minimum order quantity requirements.

Strategy: Small and Mid-Sized Brands Adopting Compact Digital Inkjet Systems to Reduce Outsourcing

Over 65% of mid-market beverage companies now utilize desktop-scale digital printers for short-run productions. These systems handle batches as small as 500 cups with professional-grade print resolution (1200 dpi), enabling cost-effective entry into custom packaging. The strategy aligns with consumer demand for hyper-localized branding while maintaining margins in competitive markets.

The Future of Smart Packaging and Digital Integration in Cup Printing

Smart Packaging Meets Digital Printing: QR Codes, NFC Tags, and Variable Data on Disposable Cups

The latest generation of plastic cup printing equipment lets companies put smart packaging right onto their disposable products. New tech is making it possible to include things like QR codes, NFC tags, and variable data printing all while cranking out over 4,500 cups every hour. A recent look at the beverage sector from 2024 showed pretty impressive numbers too - around seven out of ten customers actually scan those digital codes on cups to check nutrition info, collect loyalty points, or experience brand related augmented reality stuff. Big name producers are switching to UV curable inkjet systems for this work. These systems can place those smart elements with pinpoint accuracy down to less than a tenth of a millimeter. This replaces old school labeling techniques and cuts down on wasted materials by roughly 30%, which makes sense both environmentally and economically.

Interactive Consumer Experiences Through Digitally Printed Smart Cup Campaigns

When digital printing meets IoT technology, something pretty amazing happens to those everyday disposable cups. They stop being just containers and start becoming actual marketing tools. According to a recent report from the retail packaging sector back in 2023, companies that put NFC chips in their cups got way better results online. The numbers show these smart cups generated about 45 percent more social media sharing than regular printed ones. Now there are special plastic cup printing systems equipped with built-in sensors that check each print as it goes by, making sure almost every single cup (we're talking 99.9%) can be scanned properly for those limited time offers or tracking information. What does all this mean for businesses? Well, they can now push really targeted content right onto the cup itself. Think local ads tailored specifically for different regions, or even fun interactive games embedded in the design. No need for extra packaging layers anymore since everything lives right there on the cup's surface.

FAQ

What is the advantage of digital inkjet printing over traditional screen printing?

Digital inkjet printing offers greater flexibility, especially for small batches, with a 43% faster setup time and the ability to achieve 1,200 dpi photo-realistic prints without screen setups.

How does automation enhance plastic cup printing efficiency?

Automation, including robotic arm integration and multi-station machines, reduces manual handling by 90% and enables inline processes such as UV curing and thickness verification, enhancing production speeds and operational efficiency.

What role does pre-treatment play in improving print quality on plastic cups?

Pre-treatment methods like corona and plasma etching enhance ink adhesion on plastic surfaces by modifying the surface at a microscopic level, leading to improved print durability and appearance.

How do smart packaging and digital integration benefit the beverage industry?

Smart packaging with QR codes, NFC tags, and variable data creates interactive consumer experiences and enhances marketing efforts while reducing material waste and improving production efficiency.

Table of Contents

- Digital Inkjet Printing for Plastic Cup Printing Machine Revolutionizes Production Lines

- High-Speed Digital Cylinder Printers Enable Mass Customization

- Integration of Automation in Cup Printing

- Precision and Speed Benchmarks

- Comparison of Key Plastic Cup Printing Machine Methods and Print Quality Outcomes

-

Enabling High-Quality Prints: Pre-Treatment and 360-Degree Helical Printing Innovations

- Pre-treatment methods (corona and plasma) enhance ink adhesion on plastic surfaces

- Case Study: Leading manufacturer’s plasma treatment increases print durability by 40%

- 360-degree helical printing enables seamless, full-wrap cup designs

- Trend: Consumer demand for customized cup designs drives adoption of full-wrap digital systems

-

Sustainability, Efficiency, and the Shift Toward In-House Plastic Cup Printing

- Efficiency Gains Through Integrated Digital Workflows and Reduced Changeover Times

- Reducing Label Waste and Packaging Materials via Direct Digital Printing

- In-House Plastic Cup Printing Advantages: Faster Turnaround, Design Control, and Cost Savings

- Strategy: Small and Mid-Sized Brands Adopting Compact Digital Inkjet Systems to Reduce Outsourcing

- The Future of Smart Packaging and Digital Integration in Cup Printing

- FAQ