Material Composition and Substrate Challenges about Plastic Cup Printing Machine

PET Plastic vs. Poly-Coated Paper: Structural and Chemical Differences

Printing machines for plastic cups run into some pretty specific problems when we compare them to those used for paper products because different materials behave so differently. Take PET plastic for instance it has this super smooth, non-absorbent surface with around 35 to 40 dynes per cm surface energy. That's totally different from what happens with poly-coated paper which actually consists of several layers including cellulose fibers mixed with LDPE coatings about 45 to 50 micrometers thick. Because PET repels water naturally, printers need special solvent based inks to stick properly. Paper on the other hand works great with water based inks since its coating lets them penetrate. This fundamental difference between how these materials interact with ink is really what drives most of the engineering decisions behind modern printing equipment design.

| Material | Surface Energy (dynes/cm) | Coating Thickness | Optimal Ink Type |

|---|---|---|---|

| PET Plastic | 35-40 | N/A | Solvent-based |

| Poly-coated Paper | 50-55* | 45-50 µm | Water-based |

| *Post-corona treatment |

Coating Technologies in Paper Cups and Surface Energy in Plastics

Paper cup printing equipment these days typically coats polyethylene onto surfaces using extrusion methods around temperatures between 180 to 200 degrees Celsius, which helps form those all important moisture barriers we need. When it comes to plastic materials though, things work differently. Most plastic systems depend on something called corona treatment, usually somewhere in the range of 2 to 4 kilowatts per square meter. This process boosts the surface energy of PET materials by about 40 percent, making sure the ink sticks properly when printed. Without this treatment, plain old PET shows roughly 25 percent less adhesion according to those standard ASTM D3359-23 cross hatch tests everyone refers to. That's why most manufacturers bother with the extra step before printing anyway.

Impact of Material Properties on Print Adhesion and Durability

The difference in durability between materials stands out quite clearly. Prints cured with UV light on plastic can last through about 50 industrial washing cycles before showing wear, while paper with its biodegradable coatings just doesn't hold up as well against abrasion. Looking at flexographic press performance numbers from FTA's 2023 report, we see around 94% ink transfer efficiency when working with coated paper compared to only 82% on regular plastics. Because of these challenges, most modern plastic cup printing equipment comes equipped with either plasma treatment units or corona modules built right into the system. These additions help maintain good print quality despite the inherent difficulties of printing on plastic surfaces.

Printing Technologies for Plastic and Paper Cups

Flexographic and Inkjet Printing in Plastic Cup Printing Machine Systems

Most plastic cup printing equipment today relies on either flexographic or inkjet technology. Flexo systems are the go-to choice for large scale operations since they work well with those common plastics like polyethylene and polypropylene. These machines can crank out over 1,200 cups every single minute according to Packaging World from last year, which explains why factories love them for big batch runs. On the other hand, industrial grade inkjet printers have their own advantages too. They use those special piezo electric print heads that create vibrant, photo quality images right onto the cups. Plus these printers handle variable data printing so companies can run limited edition designs without much hassle for their marketing efforts.

Adaptations for Water-Based Inks and Coated Paper Substrates

Printing on paper cups needs special adjustments because of their porous yet poly-coated surfaces. Before printing, most facilities run pre-coating units that put down sealants to stop water based inks from seeping into the fibers. This is something the 2024 Sustainable Packaging Report actually highlights as pretty important for quality control. When it comes to plastic cups though, manufacturers have different challenges. They typically work with adhesion promoters since plastics naturally resist ink sticking to them. There's been some interesting developments lately too. Hybrid inks now exist that look good on both paper and plastic materials without fading quickly. Plus these newer formulas cut down on harmful VOC emissions somewhere around 18 to maybe 22 percent compared to older solvent based alternatives. Makes sense when companies want cleaner production processes without sacrificing print quality.

Pre-Treatment and Drying Mechanisms: Enhancing Print Quality

Surface preparation and curing differ significantly between materials:

- Plastic cups undergo corona treatment (3.8 - 4.2 kW/m²), raising dyne levels from 30-34 to 40-44 for reliable ink anchoring

- Paper cup machines use infrared drying tunnels (70-90°C) to cure inks without deforming thin walls

- UV-LED curing reduces energy consumption by 37% in dual-substrate printers (EcoPrint Consortium 2023)

These optimized processes allow plastic cup printing machines to achieve scratch resistance beyond 500 cycles in abrasion testing, while maintaining FDA-compliant food contact safety in paper systems.

Design Flexibility and Custom Branding Capabilities

Full-Wrap Graphics on Plastic Cups vs. Branding on Paper Cups

Printing machines for plastic cups can do 360 degree printing on PET materials because the surface doesn't absorb ink, so the images stay sharp without bleeding through. When it comes to paper cups though, things get tricky. The printers have to work with these poly coated surfaces which take longer to dry, making them about 32 percent slower according to FlexoTech's research from last year. For companies wanting their brand to stand out, plastic is definitely better. Full wrap designs on plastic maintain around 98% color accuracy across all surfaces while paper only manages about 76% when we're talking about those partial print jobs most brands settle for.

Print Resolution, Color Fidelity, and Customization Options

The best plastic cup printing machines can produce images at around 1200 dpi resolution thanks to their UV cured ink technology, which makes it possible to create those shiny metallic effects and smooth gradients that just don't work well on the rough surface of paper. When we look at paper based systems that rely on flexographic printing, they typically hit about 600 dpi, and their color range ends up being roughly 18 percent smaller because the paper absorbs so much of the ink. Manufacturers are getting creative these days though. The plastic printing equipment now incorporates biodegradable options for eco friendliness, while many paper systems have started using laser treatments before printing to improve how well the ink sticks to surfaces, giving them almost a 40 percent improvement in adhesion according to recent tests.

Consumer Perception: Eco-Labeling vs. Actual Recyclability

Even though around 67% of people think paper cups are green according to EcoPack's 2023 report, the truth is quite different. Just 12 out of every 100 poly-coated paper cups actually get recycled, while PET cups manage about 29%. The industry is trying something new though. Many folks who run those plastic cup printing machines now put QR codes on their products so customers can learn what happens after they throw them away. Companies have seen better results too, with trust going up roughly 22% when these codes explain where things end up. Still worth noting though, looks still matter a lot for spontaneous buying decisions. About half of all impulse purchases depend heavily on how attractive something appears at first glance.

Production Efficiency, Cost, and Sustainability Comparison

Manufacturing Speed, Throughput, and Integration Capabilities

The plastic cup printing machines can crank out between 1,200 to 1,500 cups every single minute thanks to those rotary flexo printing systems. These beat their paper counterparts by roughly 25 to 30 percent because plastic just handles better during production. Paper systems run at high speeds too but need really careful alignment when working with coated materials, which brings their output down to around 900 to 1,100 cups per minute. Machines that handle both types of cups now come equipped with built-in robotic arms. This setup cuts down on the time needed to switch between materials by about forty percent, making operations much more flexible overall according to recent research from ScienceDirect back in 2023.

Energy Consumption and Carbon Footprint in Cup Production

When it comes to making cups, plastic actually requires about 40 percent less energy compared to paper products. However, there's a catch when looking at carbon emissions. Plastic cups release around 2.1 kilograms of CO2 equivalent for every 1000 units produced, while paper cups clock in at 1.4 kg according to research published in the Journal of Cleaner Production back in 2023. The reason for this difference lies mainly in how paper gets treated before becoming cups. Paper needs those energy hungry coatings applied during manufacturing, whereas plastic has its own environmental issues stemming from reliance on fossil fuels right from the start. Some manufacturers are starting to implement solar thermal drying technology though, which helps cut down overall energy consumption by approximately 18% regardless of whether they're working with plastic or paper materials.

Cost Analysis at Scale: Plastic vs. Paper Cup Printing Machines

At 10-million-unit volumes, paper cup printing costs 18% more than plastic due to:

- Water-based ink curing infrastructure ($220k-$350k premium)

- Polyethylene coating applicators requiring 30% more maintenance

- Higher substrate waste (6.2% vs. 4.1% for plastic)

Dual-material systems lower per-unit costs by 12% when operating at a 60/40 paper-to-plastic ratio (ScienceDirect 2023).

Sustainability Trends: Compostable Coatings and Hybrid Materials

Innovations in 2024 include:

- PLA-based compostable layers replacing 82% of polyethylene in paper cups

- Hybrid PET-pulp composites offering plastic-like durability with 50% bio-content

- UV-LED curing eliminating 90% of solvent emissions

A 2023 lifecycle analysis shows next-gen materials could reduce the carbon footprint of cup printing by 34% by 2026 through cellulose nanofiber reinforcements and algae-derived inks.

Market Leaders and Innovations in Dual-Substrate Printing

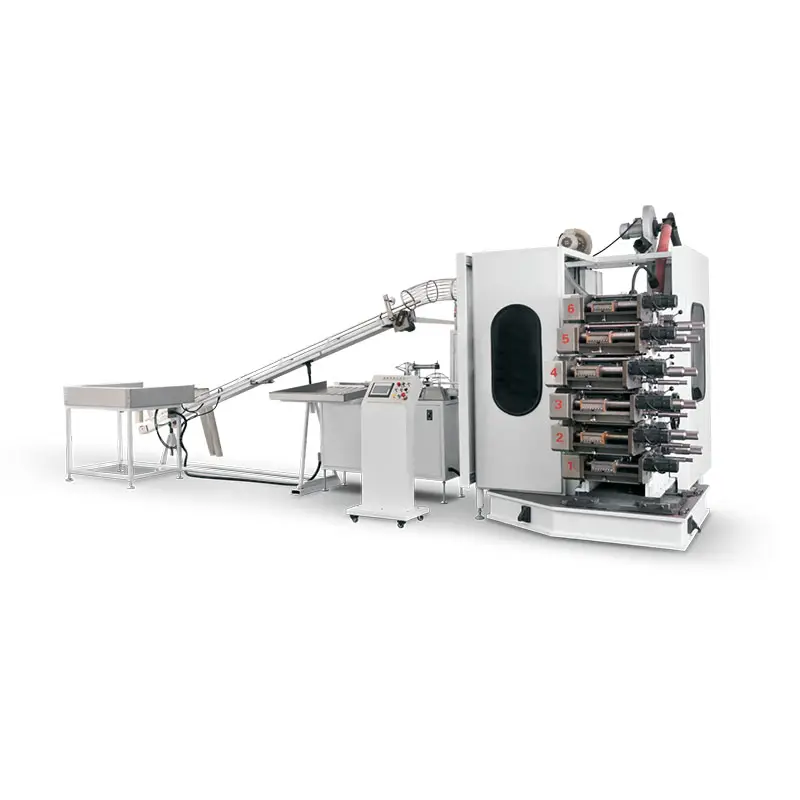

ZHEJIANG GUANGCHUAN MACHINERY CO LTD: Integrated Plastic and Paper Cup Solutions

ZHEJIANG GUANGCHUAN MACHINERY CO LTD has become a major player in dual substrate tech, creating hybrid systems that bring together PET and poly coated paper cup manufacturing on one platform. The company's special nozzle design gets about 98 percent material usage going, thanks to its ability to adjust ink thickness and cure temps automatically according to what's needed at any given moment, as noted in the latest 2024 Printing Tech Market findings. What makes this really stand out is how it cuts down on those annoying printhead swaps that used to take so much time. Setup times drop around 40%, which means production lines can get running faster. And for average sized drink companies, this translates into saving roughly 32 metric tons of waste each year compared to traditional methods.

Emerging Dual-Substrate Cup Printing Machines and Future Outlook

The latest systems come equipped with AI that recognizes different substrates, so they can switch automatically between plastic and paper without needing anyone to recalibrate manually. Take hybrid machines with UV LED curing for instance these dry about 27 percent quicker on wax coated paper compared to old fashioned infrared systems, and still manage to hit those 1200 dpi marks on PET materials. According to Sustainable Packaging Forecast 2024, compostable PLA coatings could grab around 58% of the paper cup market by 2027. That's why manufacturers are working hard on developing bio based inks that work well with both polymer films and cellulose fibers. The industry needs this kind of flexibility and sustainability without slowing down production speeds.

FAQ

What types of inks are required for printing on PET plastic and poly-coated paper?

PET plastic requires solvent-based inks due to its smooth, non-absorbent surface, while poly-coated paper works well with water-based inks.

How does corona treatment affect PET plastic cup printing machine?

Corona treatment increases the surface energy of PET plastic by about 40%, which improves ink adhesion.

Are plastic cups more eco-friendly than paper cups?

While plastic cups require less energy to produce, they emit more CO2 than paper cups. However, only 12% of poly-coated paper cups are recycled, compared to 29% of PET cups.

Table of Contents

- Material Composition and Substrate Challenges about Plastic Cup Printing Machine

- Printing Technologies for Plastic and Paper Cups

- Design Flexibility and Custom Branding Capabilities

- Production Efficiency, Cost, and Sustainability Comparison

- Market Leaders and Innovations in Dual-Substrate Printing

- FAQ